Facilities

Process Flow

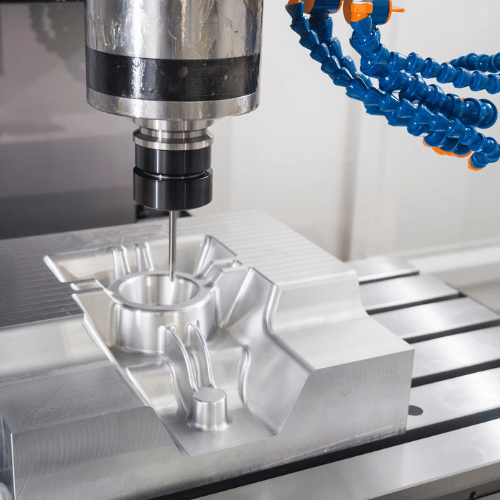

Tool Making

The first stage of the process is designing and developing a tool for wax injection of the specific part using a CNC machine.

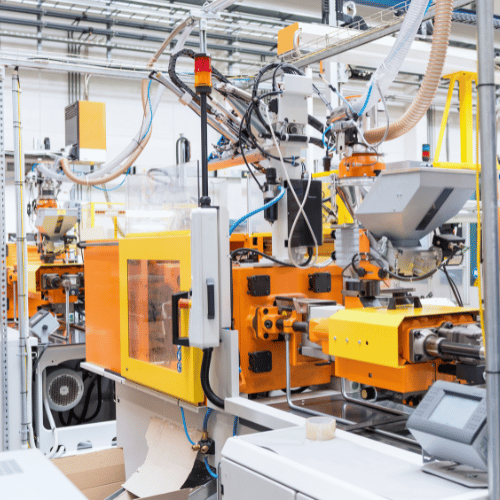

Wax Injection

This process creates a wax model of the final part. Molten wax is injected into a mold to form the replica.

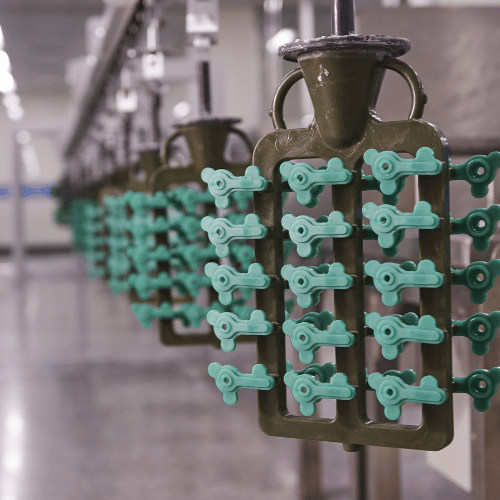

Pattern Assembly

Wax patterns are joined by gates to a central wax rod, forming a tree-like structure that is fixed to a pouring cup for casting.

Shell Coating

The wax tree is first dipped into ceramic slurry and then sprinkled with sand inside a controlled coating chamber.

Dewaxing

The ceramic-coated wax trees are dried in a humidity-controlled chamber before removing the wax.

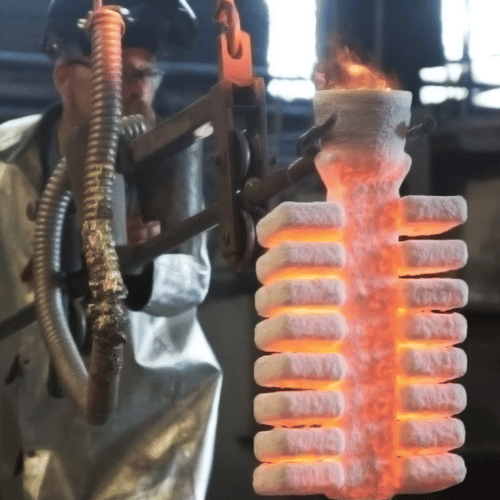

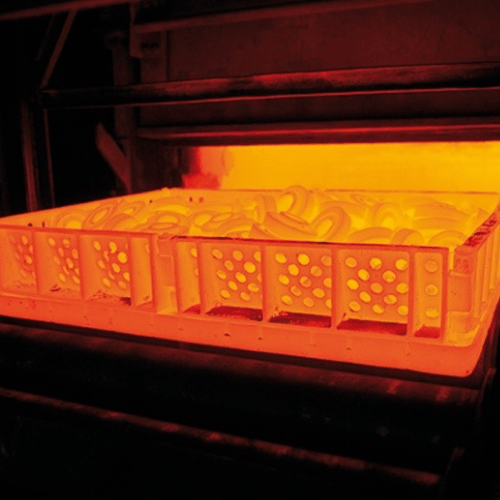

Pouring

Dewaxed shells are preheated to a specific temperature before being filled with molten metal. As the metal cools down, the parts, gates, tree, and pouring cup solidify to form the final casting.

Shell Removing

After the molten metal has solidified and cooled down, the ceramic shell is removed by using a pneumatic knockout machine, which vibrates and breaks away the shell from the casting.

Heat Treatment

After separating the cast parts from the central tree, they undergo heat treatment at controlled temperatures to achieve a uniform microstructure and the desired mechanical properties.

Finishing

The cast products undergo finishing processes such as shot blasting, grinding, and machining to achieve a smooth and precise surface finish.

Final Inspection

Each product undergoes final inspection and necessary testing to verify dimensional accuracy and ensure it meets the required mechanical properties.